Dynstat bending test and impact test, DIN 53435

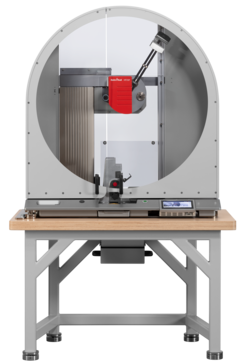

In 2017, the existing DIN 53435 standard was fully revised and updated. The contents of DIN 53435 and its associated instrument standard,DIN 51230 , were combined. By aligning this standard with other standards for impact testing, ISO 179-1 for Charpy impact tests, ISO 180 for Izod and ISO13802 regarding instrument characteristics and calibration, the body of standards are now harmonized and up to date with current technology. The use of notch type A for Dynstat impact bending tests is new to this standard. This notch type is also used in Charpy and Izod standards. A flexure tool with electronic torque measurement has been introduced for static flexure tests. Precision data collected from these test methods and the notch types now approved provide clues to possible areas of application.

- The Dynstat bending test is designed as a four-point bending test.

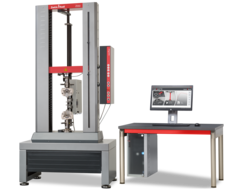

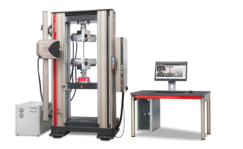

- With the new test fixture, the test can now also be performed on one testing machine. The support spans are 12 mm and 2 mm at the start of the test. This means a specimen as small as 15 mm in length can be tested with this method. Flexural deformation is produced by the test fixture's rotational movement. The test result is the maximum flexural stress measured during the test. It is calculated using the bending moment and the resisting moment of the specimen. If the specimen does not break by the time it reaches the Dynstat bending angle defined by the standard, the flexural stress is measured at this point.

- Large discrepancies in material characteristics of the finished part, due to morphology effects, occur in molded parts. These can be measured and compared with this test method.

- In round robin tests, very good conformity could be verified between the measured values according to the previous measurement method (torque application via pendulum arm) and the electronic measurement of the torque. The repeatability of the measured values is significantly improved by the uniform application of the bending angle and by the electronic torque measurement.

Reviews

There are no reviews yet.